How Octagon leveraged WebIQ to accelerate innovation

Through a strategic partnership with Smart HMI, a Beijer Electronics company, Octagon has transformed its HMI platform to meet the demands of modern manufacturing. By integrating WebIQ, Octagon has achieved faster time-to-market, enhanced modularity, and a user experience that empowers both operators and management. Smart HMI’s responsive support and future-proof technology have been key enablers in Octagon’s journey to remain a technology pioneer in the plastics industry.

The challenge: Modernizing while maintaining independence

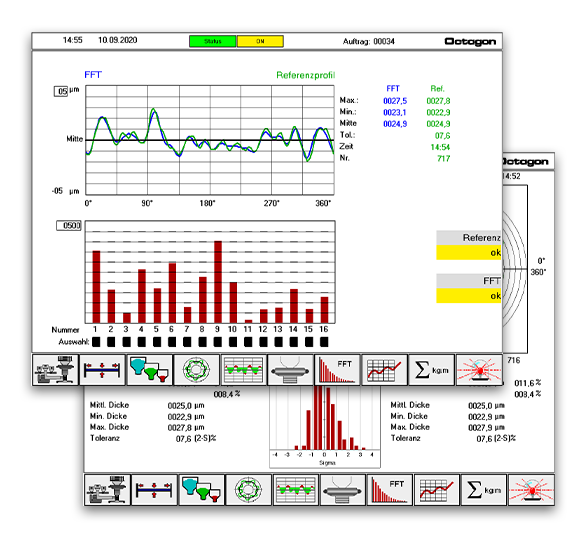

Octagon, a German-based leader in blown film extrusion systems, has built its reputation on innovation and independence. Known for developing its own hardware and software, Octagon faced a turning point with the launch of a new generation of electronics. The company needed a modern, scalable HMI solution, but without the time or resources to build a new HMI editor from scratch.

Octagon’s goal was to replace its fragmented HMI systems, each tailored to a specific product, with a unified, modular platform that could scale across its entire portfolio.

“We wanted to stay independent,” says Samuel Janzen, Development Engineer at Octagon. “But we did not want to build our own editor again. Time-to-market was one of the main reasons we chose Smart HMI as a partner.”

The solution: A modular, web-based HMI powered by WebIQ

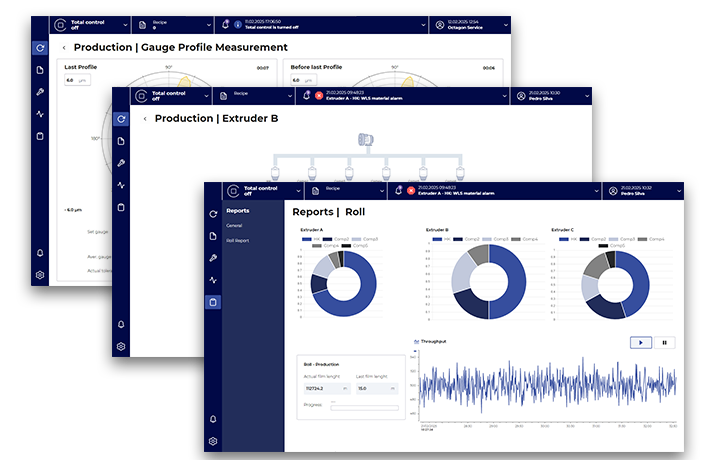

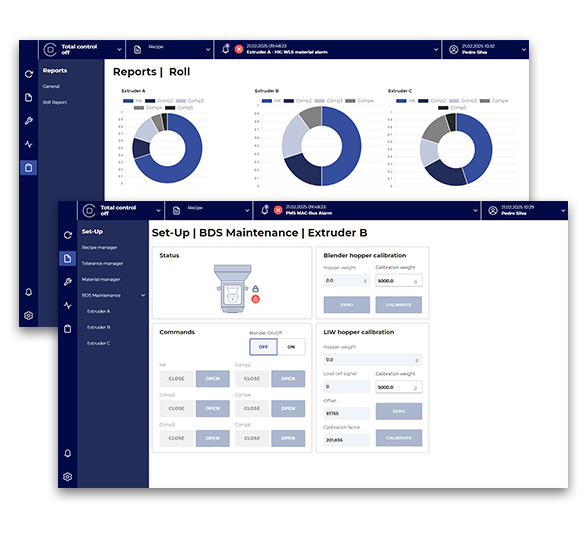

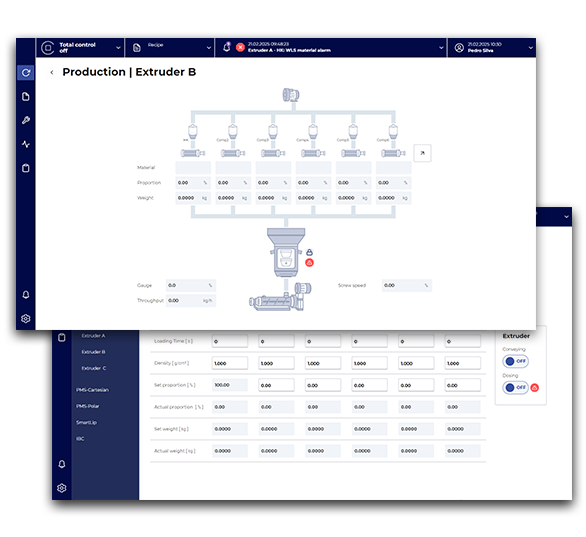

With WebIQ, Octagon now delivers a single, configurable HMI project that adapts automatically to the modules present in each system. This modularity mirrors Octagon’s product architecture and significantly reduces engineering time.

“Earlier, we had a specific HMI for each product,” explains Mr. Janzen. “Now, with WebIQ, we can configure everything much easier. Changing languages, for example, is simple, when we had a new customer in Colombia, we simply just entered the translation.”

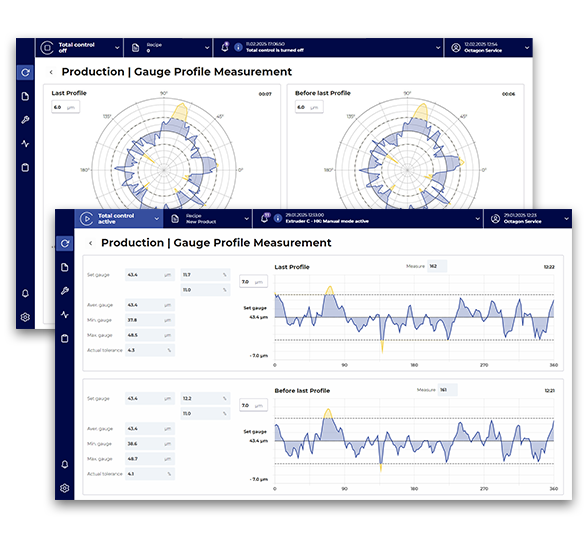

The new HMI is intuitive and responsive, offering smartphone-like interaction that even unskilled operators can use with ease. This has led to faster product changes, fewer errors, and quicker onboarding.

For management, the system provides powerful tools for performance tracking, diagnostics, and reporting. “The HMI isn’t just for operators anymore,” says Janzen. “It’s also for management who now can analyze performance data and make better data-driven decisions.”

Why WebIQ was the right choice

Octagon evaluated several competitors but found that many lacked the maturity and features needed for industrial deployment. WebIQ stood out for its:

01

Future-proof architecture:

02

Fast and easy start

03

Customization and flexibility

04

Outstanding support

What began as a single-product implementation is now expanding across Octagon’s full product line, with hundreds of screens and thousands of variables. The system continues to grow, thanks to its ease of integration and scalability.

Delivering value to Octagon and their customers

With WebIQ, Octagon has delivered a modern, modular HMI that enhances usability, reduces engineering time, and supports both operators and management. Customers benefit from faster setup, intuitive controls, and better access to performance data, while Octagon maintains its independence and leadership in innovation.

“WebIQ already has a long story and a proven track record behind it,” concludes Janzen. “It gives us confidence. It is a future-proof solution that grows with us.”

Sign up and experience WebIQ today!