Nedschroef Machinery modernizes machine control with WebIQ

Nedschroef Machinery has significantly advanced its machine control capabilities through a strategic collaboration with Smart HMI, a Beijer Electronics company. By implementing a modern, web-based Human Machine Interface (HMI) built on the WebIQ platform, the company has enhanced usability, enabled remote access, and laid the groundwork for future-ready, digitalized manufacturing.

Design by CaderaDesign

Outdated systems in a rapidly evolving industry

For over a decade, Nedschroef Machinery utilized Pro-face-based HMIs to operate its cold and warm metal forming machines. While these systems were dependable, they increasingly struggled to meet the demands of modern manufacturing environments. The hardware was aging, software capabilities were limited, and the system lacked the flexibility required to support digital transformation and Industry 4.0 initiatives.

As the need for intuitive interfaces, remote access, and scalable solutions grew, Nedschroef identified the necessity for a future-proof HMI that could support its global customer base and streamline machine operations.

“Thanks to the close and pleasant collaboration with the Smart-HMI development team, combined with a learning-on-the-job approach, we are now able to develop and maintain our own future-ready, web-based HMIs.”

Koen Heylen, Automation Engineer, Nedschroef Machinery

The solution - a web-based, user-centric HMI platform

To address these challenges, Nedschroef Machinery partnered with Smart HMI to develop a next-generation HMI using the WebIQ framework. The result is a 19” multi-touch interface that combines modern aesthetics with intuitive functionality.

The new HMI is built entirely on web technologies, making it device-agnostic and accessible from any modern browser, whether on a desktop, tablet, or smartphone. This flexibility allows operators, technicians, and engineers to monitor and interact with machines remotely, improving responsiveness and enabling smarter decision-making.

The development process was highly collaborative. Engineers from both companies worked closely with end users, conducting interviews, creative workshops, and usability testing to ensure the interface addressed real-world needs. This approach also enabled Nedschroef’s internal teams to gain the expertise needed to independently develop and maintain the HMI moving forward.

Key features and customer benefits

The new HMI platform introduces a range of features designed to enhance machine operation and user experience:

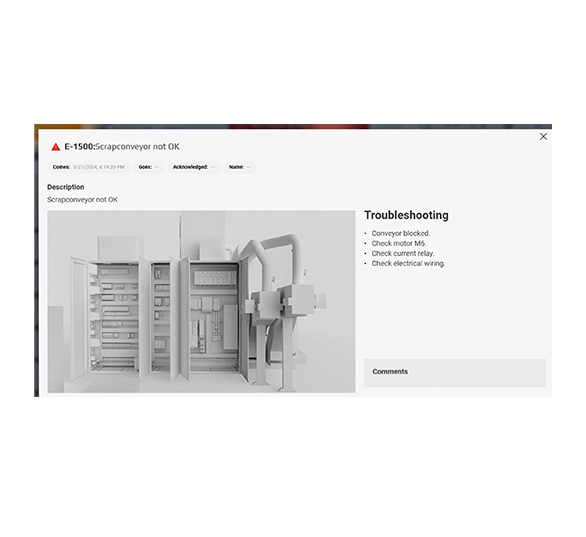

Advanced alarm handling

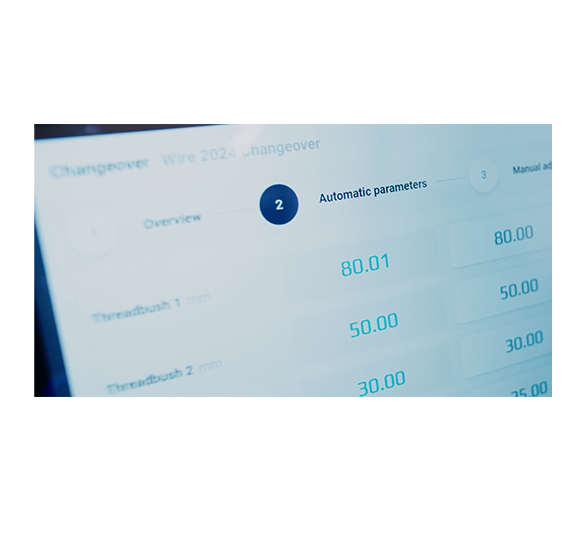

Enhanced recipe management

Guided changeovers

Integrated documentation

Remote access

These features not only improve operational efficiency but also enhance the overall user experience, making machine control more intuitive and accessible.

A strategic step toward Industry 4.0

This collaboration represents more than a technical upgrade, it marks a strategic milestone in Nedschroef Machinery’s digital transformation. By integrating Smart HMI’s advanced solutions, Nedschroef is delivering smarter, more connected machines that align with the evolving demands of modern manufacturing.

Why Smart HMI was chosen

Nedschroef Machinery selected Smart HMI and the WebIQ platform based on several strategic advantages:

01

Web-based architecture

02

Device independence

03

Collaborative development model

04

User-centered design expertise

05

Future-ready technology

Sign up and experience WebIQ today!